Individual Project | 9 Weeks | 2020

Brief

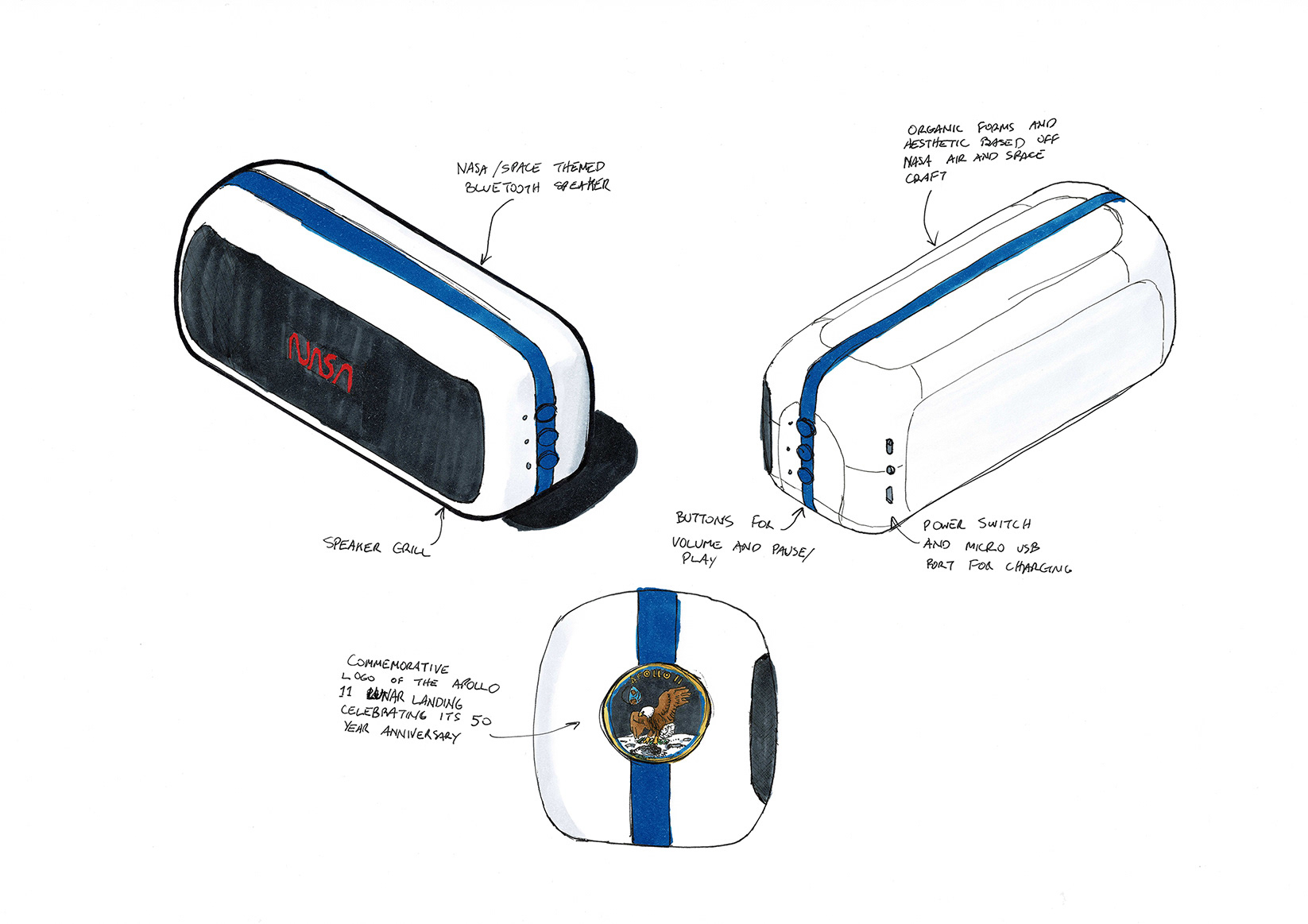

This speaker was designed around existing off-the-shelf components and themed around NASA, in particular the 50th anniversary of the Apollo 11 lunar landing.

Process

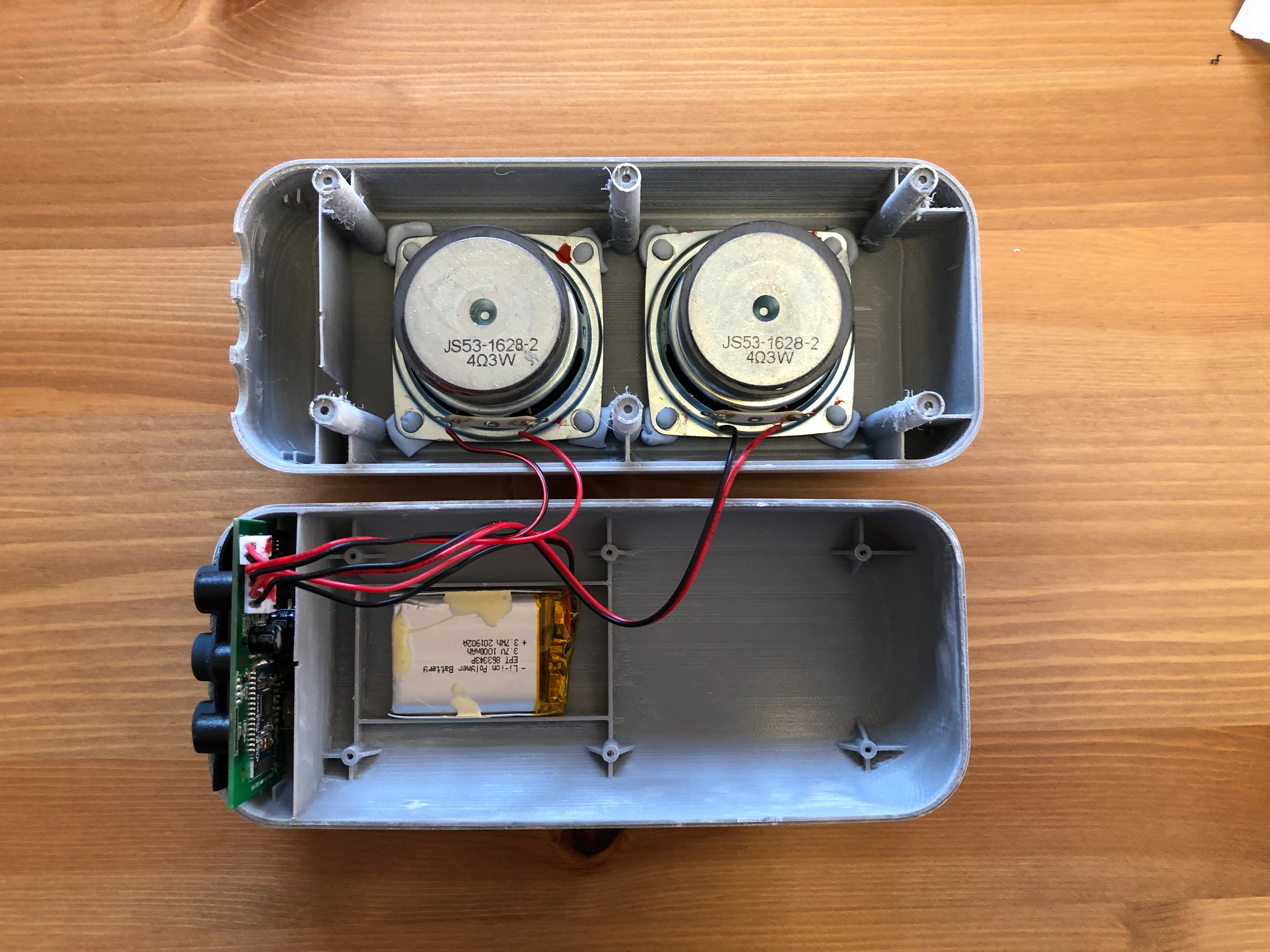

Branding and design style research was conducted to capture the visuals and aesthetics of NASA. Initial design sketches, concepts, and foam prototypes were generated to implement NASA’s aesthetics into the speaker. Extensive CAD modelling was undertake and technical drawings of each part were produced. A working prototype of the final design was also made. The parts designed were 3D printed, sanded, and painted. The off-the-shelf parts were housed within the speaker components thus completing the assembly.

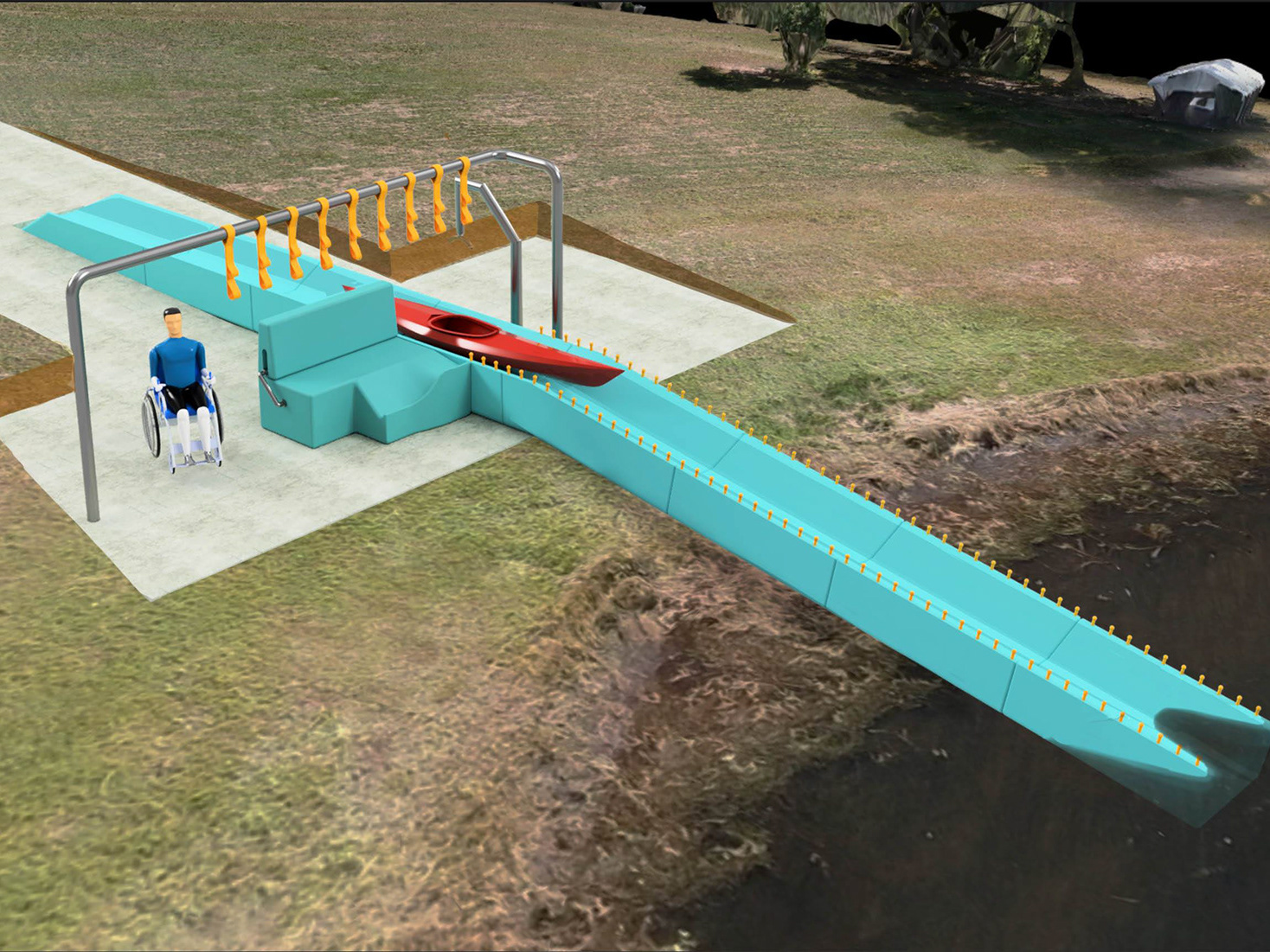

Initial concept sketches and foam prototypes were created to gain a sense of scale and proportions.

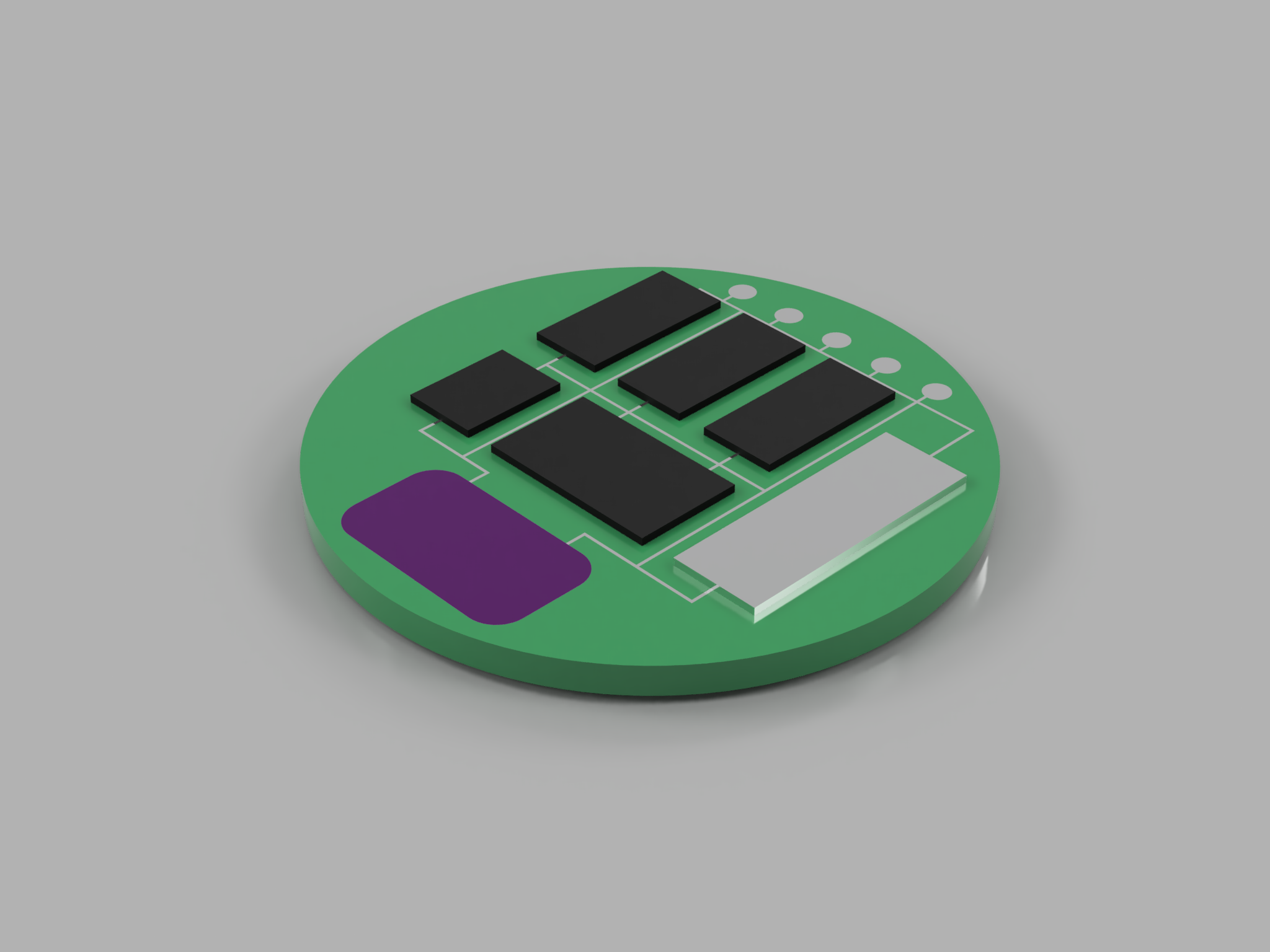

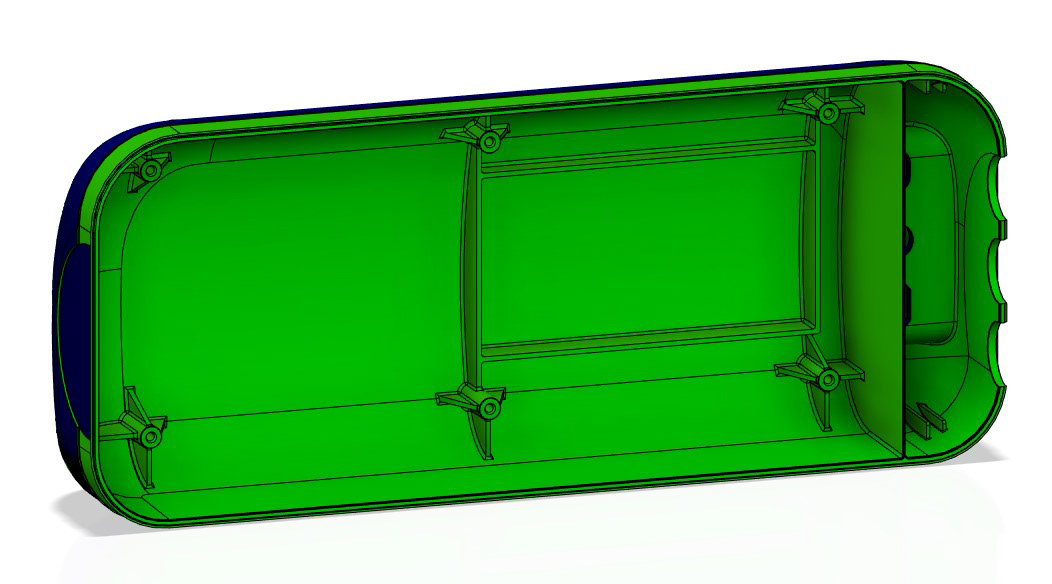

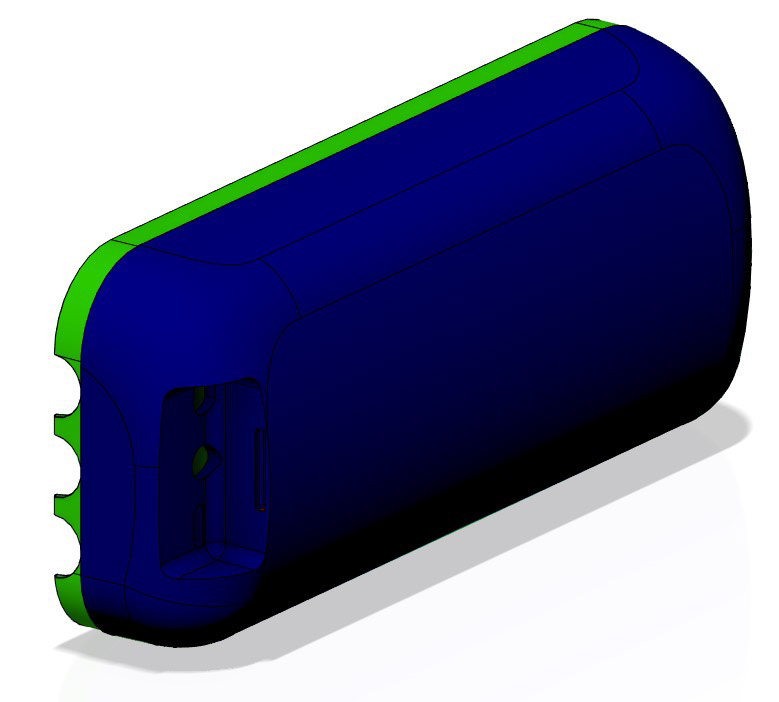

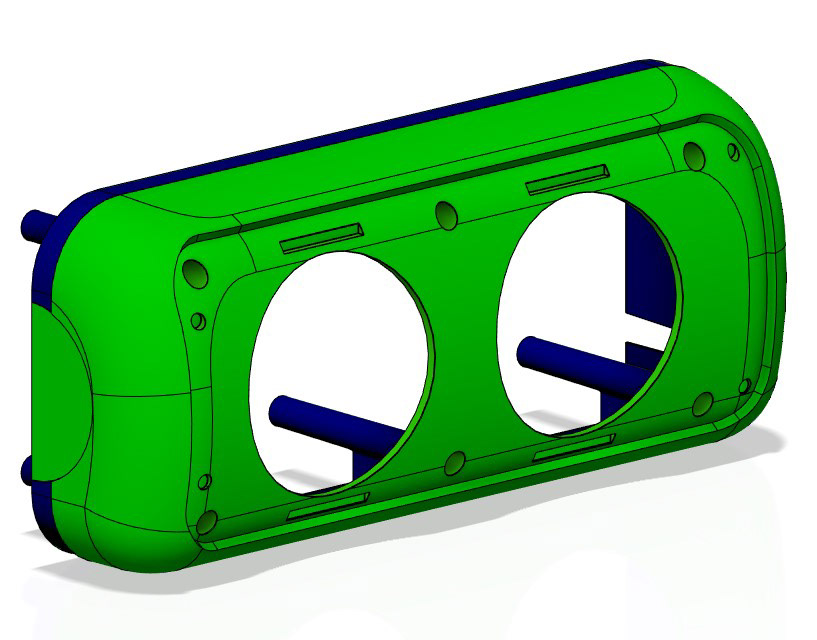

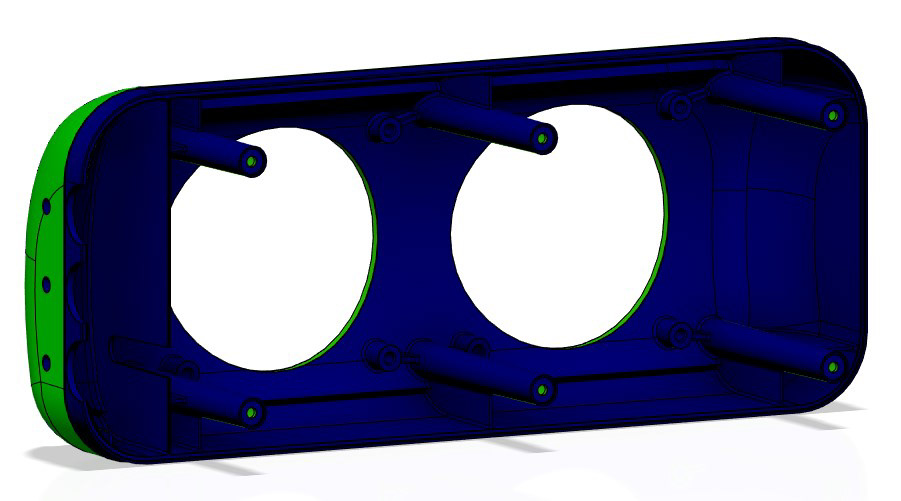

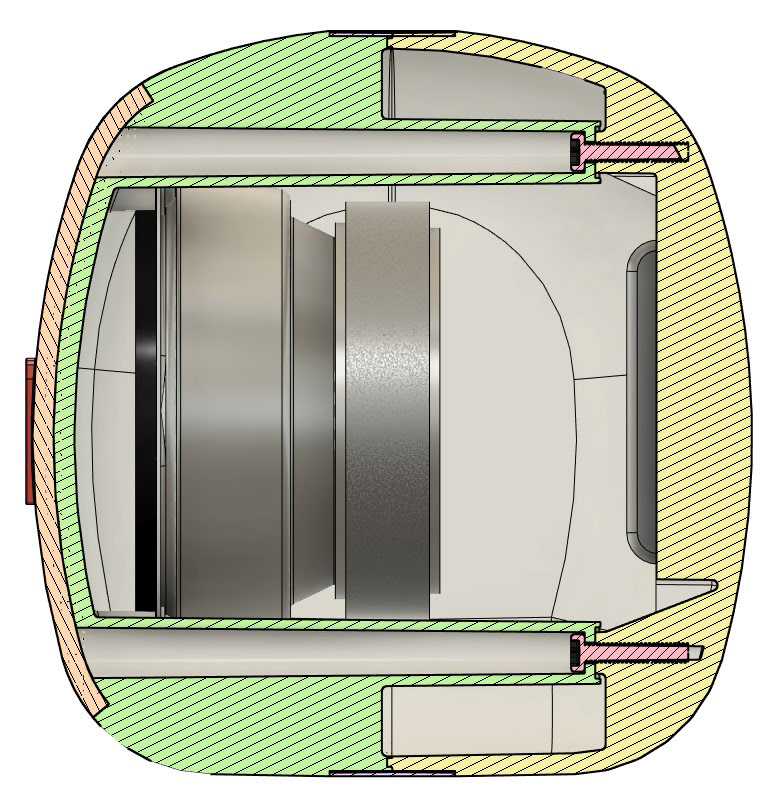

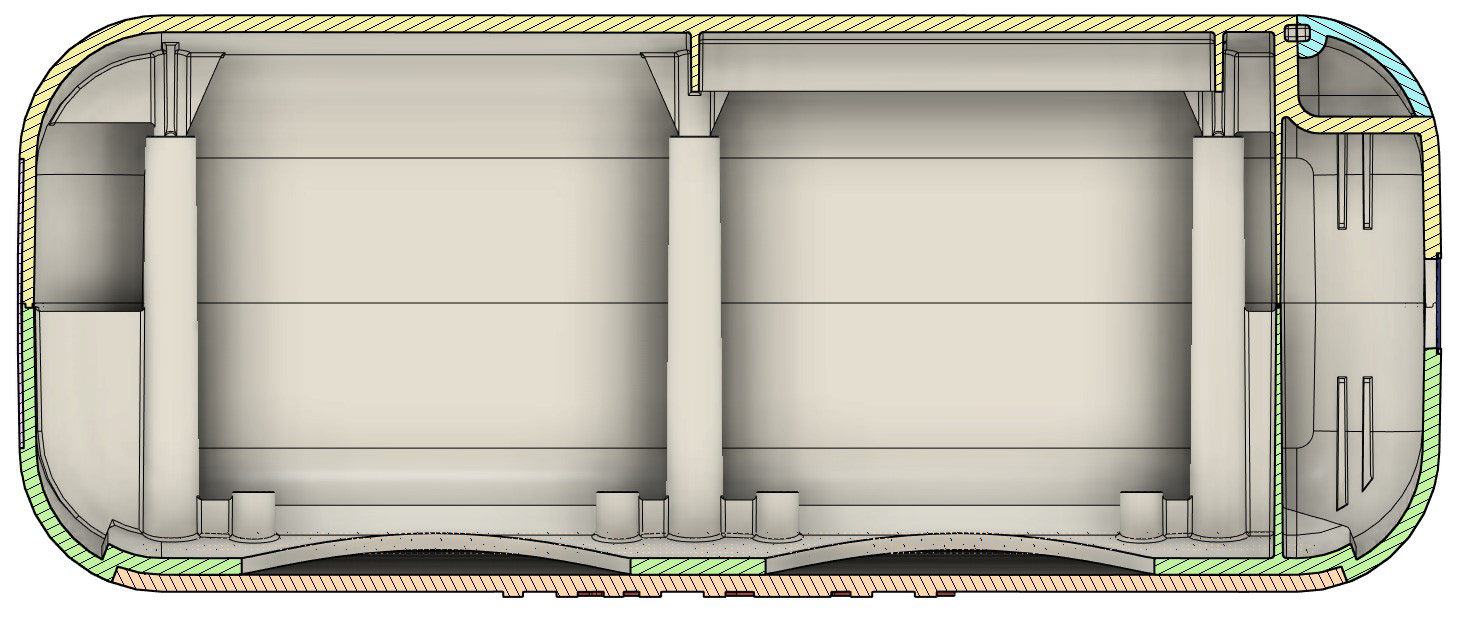

Draft and sectional analysis were used to ensure the CAD parts were fit for manufacture. Green and blue colouring indicates that there is sufficient draft for injection moulding.

Design

The design of the speaker required two injection moulded halves that fit together either via screws or snap-fit hooks. Each part of the speaker was needed to be designed ready for manufacture which meant research on appropriate industry design standards was crucial.

The shape and form of the speaker are meant to reflect NASA’s elegant spacecraft and aircraft yet also have some resemblance of an astronaut’s helmet at a side view. The glossy white speaker casing as well as the dark blue silicone band represent NASA’s branding and spacecraft aesthetic. The left side of the speaker features the Apollo 11 mission patch as a decal which pays homage to the commemorative nature of the product.

Bluetooth speaker exploded view

Apollo 11 mission patch

Charging port and power switch location

Sectional view of components in speaker

Component locations withing speaker

A few context images were created to provide a sense of scale of the speaker.

The final working prototype was 3D printed, sanded and painted to provide the desired surface finish and colour. Various model making techniques were implemented to achieve the a realistic and accurate representation of the final speaker design.

Below are a sample of some of the technical drawings and documentation generated for this project. Each part is manufacture ready and abides by injection moulding industry guidelines.

Software

Autodesk Fusion 360 was used for CAD modelling and rendering along with the Adobe Suite.